Industry: Semiconductor

Process: Peroxide Abatement for Piranha Acid

Benefits:

- Reliable & Scalable Peroxide Destruction

- Onsite Treatment to Eliminate Waste & Hauling

- Recovery & Recycling of Sulfuric Acid

Background

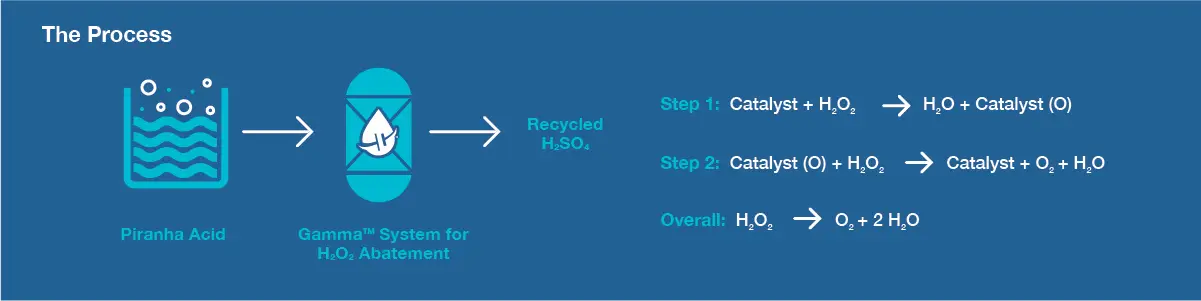

Hydrogen peroxide (H₂O₂) is crucial in microelectronics manufacturing, serving as a powerful oxidizing agent for cleaning, etching, and surface treatment processes. Piranha solution, a 3:1 to 7:1 mixture of sulfuric acid to peroxide, and base piranha, a 5:1:1 mixture (water/ammonia/peroxide), are standard chemistries in microelectronics to remove photoresist and organic material residue from silicon wafers. This wastewater poses significant risks to downstream reuse membranes, primary and secondary waste treatment equipment, and the environment, if discharged. In some countries, new regulations have been established for transportation of waste peroxides restricting [H₂O₂] to ≤2%, so onsite abatement is necessary to maintain operations. No viable solutions existed for effective abatement of piranha acid.

Challenges

A semiconductor original equipment manufacturer (OEM) invested >$1M USD unsuccessfully developing a peroxide abatement solution for piranha acid to enable onsite acceptance testing, which is required to release and ship processing equipment. The end-user (Fab) also sought piranha acid treatment to avoid violating its zero-waste policy for such equipment. The piranha acid had an operating pH of 0.3 with ~4% peroxide. Catalase was not viable due to the elevated peroxide concentration and extreme pH, while activated carbon decomposed in the piranha acid. Additional challenges were limited treatment footprint and the need for zero-byproducts to eliminate needs for secondary treatment.

Challenge

Regulations & initiatives prevent hauling/disposal

OEM delivery & manufacturer fulfillment are threatened

No viable solutions due to extreme acidity and elevated [H₂O₂]

Solution

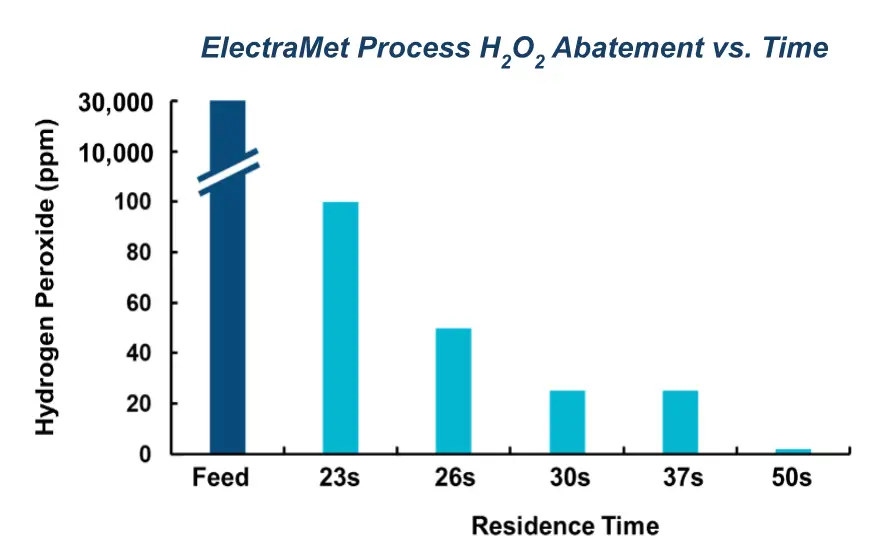

Gamma system reliably reduced H₂O₂ to H₂O & O₂ with onboard monitoring

Scalable systems to reliably destroy peroxide from piranha acid

Onsite redox-active media with small footprint and no detrimental byproducts

Impact

Eliminated hauling & disposal costs, logistics, and risks

Globally deployable and consistent results

Enabled zero-waste, zero-liquid-discharge, and acid recycling

Proven Results | Case Study

Piranha acid is used for organics and photoresist removal at a tier 1 semiconductor equipment OEM. A piranha acid with pH of <0 and ~4% peroxide is used, which presents significant issues to on-time delivery and manufacturing planning fulfillment.

ElectraMet exceeded the OEMs expectations by delivering the following impact:

- Significant value recovery through recycled H₂SO₄ (>100,000 cubic meters of piranha makeup avoidance)

- Reduced risk to fulfillment by eliminating hauling & regulatory risks

- Attainment of elusive sustainability and zero-waste goals

- Reduced labor and employee risk associated with handling piranha acid