Industry: Microelectronics

Process: Hydrogen Peroxide Destruction

Benefits:

- Reliable H₂O₂ removal from concentrated SPM and piranha solutions

- Enable clean H₂SO₄ recovery for recycling and new revenue

- Eliminate chemicals and detrimental byproducts from process

Background

Sulfuric peroxide mixtures (SPMs) are frequently used in microelectronic and component manufacturing to remove organic contaminants from metal and substrates. Highly concentrated mixtures are used for wafer cleaning and wet etching processes within the fabs, with up to 70% H₂SO₄ and > 6% H₂O₂, known as piranha acid. Due to poor reaction efficiency at elevated [H₂O₂] and the detrimental byproducts generated at low pH, traditional solutions like peroxidase and activated carbon are not viable. The requirement for SPMs with limited abatement solutions has created significant risks for regulatory compliance and

downstream assets or processes, while significantly limiting acid reuse or recycle options.

Challenges

A tier 1 semiconductor manufacturer used a “spent” SPM (64% H₂SO₄, 6% H₂O₂) to manufacture sodium sulfate and calcium sulfate for an end customer. Due to processing limitations and impurity restrictions, only 30% of the SPM volume could be processed into product, while the remaining SPM was treated with toxic chemistry and disposed of as waste. The company goals were to attain zero-waste in the process with aspirational goals of upcycling the spent SPM into microelectronics grade H₂SO₄ (96%). Refining H₂SO₄ from ~64% to 96% requires membrane concentrators, which require [H₂O₂] at < 50 ppb. Despite significant investment, they could not identify a method to achieve their zero-waste or upcycling aspirational goals.

Challenge

Current solution could not treat waste without contamination

Zero-waste goals were unachievable

Recycling aspiration was impossible due to remaining H₂O₂ and contaminants

Solution

ElectraMet Gamma™ portfolio for oxidant abatement with SPMs

Achieved customer goals of clean H₂O₂ removal with no contaminants

Recycling aspiration was attained due to <50 ppb H₂O₂ attainment

Impact

End-product quality improvement due to chemical elimination

Quantifiable achievement of zero waste & sustainability goals at Tier 1 Fab

Realization of H₂SO₄ recycling program achieved with ROI <12 months

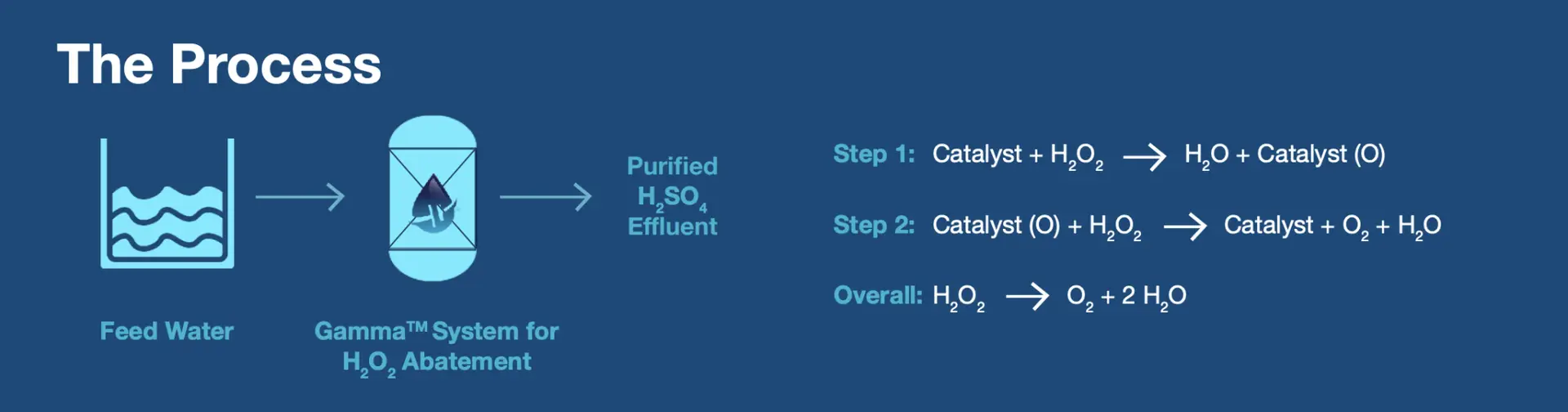

ElectraMet’s solution uses a redox-active media to catalytically break down the hydrogen peroxide from process water and wastewater streams. ElectraMet’s chemical-free process is a circular solution for handling H₂O₂ in process & waste streams, which benefits the plant, its employees, the surrounding community, and the environment. Post-commissioning, the only byproducts impacting the stream will be water (H₂O) and oxygen (O₂).

Additional observed benefits include:

(1) Reduced operator hours due to reliable catalytic destruction

(2) Increased personnel time spent on preventative maintenance for other systems

(3) Improved downstream processing performance due to low H₂O₂ effluent quality

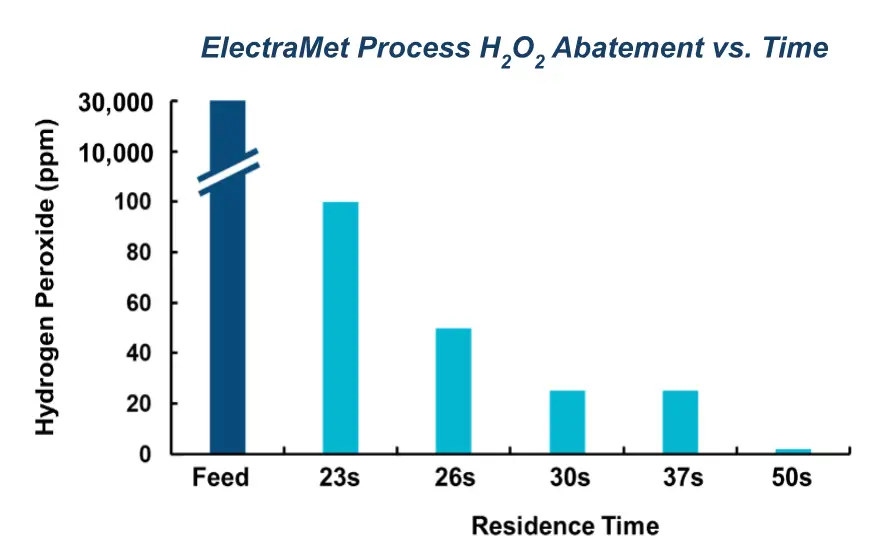

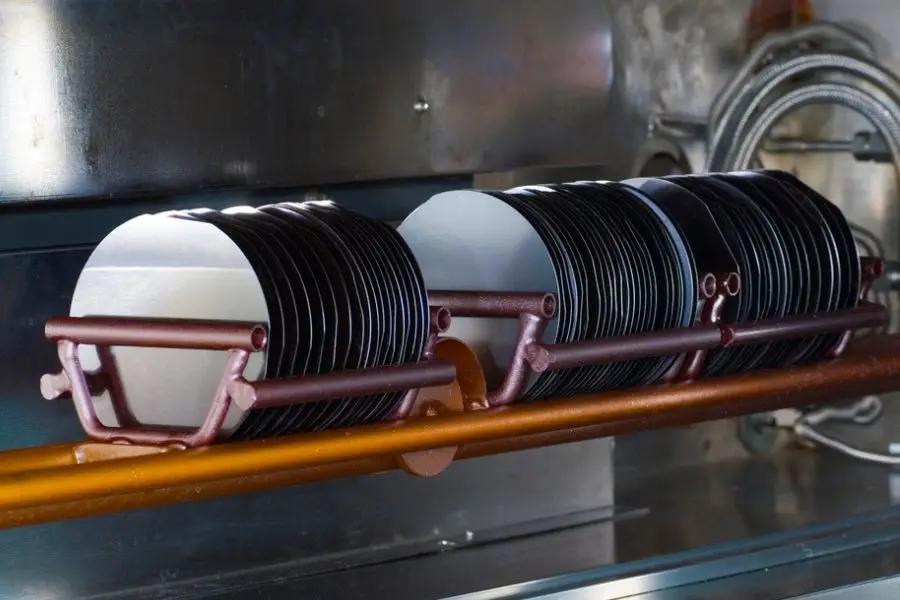

ElectraMet’s Gamma™ system incorporates this catalytic media into reaction chambers with modulated flow and monitoring to ensure specification is attained. The flow modulation enables resonance time for the media to execute the two-step destruction process and regenerate itself while in service. No chemistry or additives are required for H₂O₂ or media regeneration. Expected lifetime of the media is five years pending feed specification adherence

Proven Results | Case Study

Spent sulfuric peroxide mixture (SPM) contained 64% H₂SO4 and 6% H₂O₂. The site needed to remove peroxide while limiting byproducts to enable downstream processing.

ElectraMet’s (Redox-Active) media solution was implemented to:

(a) Deliver < 50 ppb [H₂O₂] to meet customer needs for recycle/upcycle aspiration

(b) Ensure < 50 ppb [H₂O₂] is maintained to protect membrane assets

(c) Improve end-product while achieving significant zero-waste and sustainability goals

Customer specifications were achieved through rapid and reliable destruction of H₂O₂ with a multi-pass Gamma™ system. Byproducts were eliminated and the treated effluent was pure. The fab achieved superior end-product results while acid upcycling became possible.