When Copper Becomes Infrastructure: Risk, Resilience, and Recovery

Why Copper Losses Are Becoming an Infrastructure Problem

Contents

-

Industry-Specific Implications

-

Defense Manufacturing

-

Semiconductor Manufacturing

-

Copper Mining and Processing

-

Why Copper Matters Now

Copper has always been essential. What has changed is how exposed industry has become to its availability.

For decades, copper was treated as a reliable industrial input. Widely used, broadly available, and assumed to be there when needed. That assumption is becoming increasingly fragile.

Across defense manufacturing, semiconductor fabrication, energy infrastructure, and mining, copper is now a shared dependency. Electrification, automation, and digitalization are increasing electrical intensity across industrial systems at the same time that supply growth remains slow and structurally constrained.

Recent analysis from S&P Global suggests that copper demand growth over the coming decades is not driven by a single sector or technology. Instead, it reflects multiple transitions unfolding simultaneously. AI infrastructure, grid expansion, defense modernization, and advanced manufacturing are all drawing from the same copper supply base at the same time.

What makes this moment different is not just rising demand, but how copper is being locked into long-lived systems across the economy:

Infrastructure is becoming more power-dense, increasing copper intensity per facility, per platform, and per megawatt delivered

Reliability and redundancy requirements are rising, multiplying electrical pathways, grounding systems, and backup capacity

Electrification is accelerating across multiple industries at once, reducing flexibility in how and when copper demand can be deferred

Supply expansion remains slow, constrained by long mine development timelines, declining ore grades, and processing bottlenecks

Taken together, these pressures change the role copper plays in industrial planning.

It is no longer just a commodity purchased on the market. It is infrastructure embedded in systems that must function reliably, securely, and continuously.

See how recovering copper already in circulation helps address rising demand pressure.

Related ElectraMet Resource

Copper, Defense Manufacturing, and Infrastructure

How Copper Demand Is Changing Across Industries

Copper demand is no longer concentrated in traditional construction or general electrical markets. It is being reshaped by the combined impact of multiple industries expanding their reliance on power-dense, high-reliability electrical systems. This shift reflects a structural change in industrial demand rather than a short-term market cycle.

Across semiconductor manufacturing, AI data centers, defense manufacturing, grid infrastructure, and mining operations, copper use is increasing as facilities become more electrified, automated, and performance-driven. Electrical intensity per facility continues to rise, not only because more power is required, but because systems are being designed around tighter tolerances, higher uptime requirements, and longer service lifetimes.

AI and data infrastructure are a major contributor to this trend. Modern data centers require continuous power delivery, dense electrical distribution, redundant feeders, grounding networks, and increasingly sophisticated cooling and backup systems. Copper demand grows not just with compute capacity, but with the infrastructure built to support reliability, resilience, and fault tolerance at scale.

Grid modernization adds a parallel layer of copper demand. Utilities are expanding transmission and distribution capacity to support higher industrial loads, integrate new generation sources, and harden networks against disruption. Electrified transportation contributes to this pressure, but advanced manufacturing facilities, particularly semiconductor fabs, introduce sustained, non-discretionary electrical demand that must be supported continuously.

Defense manufacturing introduces another distinct demand profile. Electrified platforms, secure production facilities, command infrastructure, and mission-critical systems are designed with redundancy and resilience as baseline requirements. These systems favor copper-intensive electrical architectures where reliability and performance take precedence over material minimization.

What distinguishes the current demand environment is timing. These sectors are not expanding sequentially, allowing supply to adjust between waves of growth. They are expanding simultaneously. As a result, global copper demand is becoming less elastic and more persistent, with fewer opportunities for deferral, substitution, or rapid efficiency-driven relief.

Several characteristics define this new copper demand landscape:

Demand is driven by long-term infrastructure and manufacturing commitments rather than discretionary consumption

Copper is increasingly embedded in fixed assets such as grids, fabs, data centers, and defense systems that remain in service for decades

Reliability, safety, and performance requirements limit substitution and design flexibility

For industrial operators and manufacturers, this shift changes how copper must be managed. Availability, cost, and supply risk increasingly influence facility siting, system design, capital planning, and long-term operational strategy, not just procurement decisions.

Copper demand is no longer simply rising. It is converging across critical industries in ways that reshape how industrial systems are built, powered, and sustained.

See how overlapping demand from AI, defense, and manufacturing is changing copper planning assumptions.

Related ElectraMet Resource

Eliminate Acidic Copper Waste Hauling

The Reality of Copper Supply Constraints

Copper supply does not scale quickly, and it rarely responds on the timelines modern industry expects. Unlike many manufactured inputs, copper production is constrained by geology, regulation, capital intensity, and geopolitics long before market pricing comes into play.

New copper mining projects require long development timelines that often span a decade or more. Exploration, feasibility studies, environmental permitting, community engagement, financing, construction, and commissioning all introduce delays that cannot be compressed easily. Even when deposits are technically viable, regulatory uncertainty and permitting challenges can extend timelines well beyond initial projections.

At the same time, declining ore grades are increasing the material, energy, and water intensity required to produce each unit of copper. Lower grades mean more rock must be mined, transported, and processed to achieve the same output. This raises operating costs, strains infrastructure, and reduces the effectiveness of incremental production increases. In many regions, higher throughput no longer translates cleanly into higher net copper supply.

Processing and refining capacity adds another layer of constraint. Smelting and refining infrastructure is capital-intensive, energy-intensive, and geographically concentrated. Building new capacity requires long lead times, access to reliable energy, and regulatory approval. As a result, downstream processing often becomes a bottleneck even when mined copper is available, limiting how quickly supply can respond to rising demand.

Even under favorable market conditions, copper supply expansion tends to lag demand growth by many years. Higher prices may incentivize future investment, but they do not resolve near-term availability or price volatility. Supply flexibility remains limited, and disruptions anywhere along the chain can ripple quickly through global markets.

Recycling plays an important role in copper supply, but it does not fully close the gap. Much of the copper already in circulation is embedded in long-lived infrastructure such as power grids, buildings, industrial facilities, and equipment. These assets remain in service for decades, delaying the return of copper to the supply stream. Recycling growth helps offset some demand, but it cannot match the pace or timing of current demand expansion.

Taken together, these constraints mean copper markets are increasingly shaped by physical and geopolitical realities rather than short-term pricing dynamics. Supply is influenced by where copper is mined, where it is processed, how quickly projects can advance, and how exposed supply chains are to regional disruption.

In this environment, copper availability becomes less elastic and more strategic. Understanding supply constraints is no longer just a market exercise. It is a prerequisite for long-term industrial planning.

Explore deeper analysis on copper supply risk, mining constraints, and processing bottlenecks.

Related ElectraMet Resource

Copper Recovery and the Circular Factory: Building Closed-Loop Sustainability

Recycling and the Limits of Circular Supply

Copper is often described as infinitely recyclable, and in theory, that is true. Copper can be reprocessed repeatedly without losing its fundamental properties. In practice, however, recycling captures only a portion of total copper flows moving through the industrial economy.

Most copper recycling systems are built around solid materials. End-of-life products, demolition scrap, manufacturing offcuts, wiring, and equipment can be collected, sorted, and reprocessed through established channels. These streams form the basis of reported recycling rates and secondary copper supply.

Dissolved copper behaves very differently.

In semiconductor manufacturing, surface finishing, mining, and other copper-intensive industrial operations, copper frequently enters wastewater streams in dissolved or highly dispersed form. Once diluted and mixed with complex chemistries, this copper no longer resembles scrap. It cannot be mechanically separated, visually sorted, or routed through conventional recycling infrastructure.

As a result, wastewater treatment systems are typically designed to remove copper to meet discharge limits, not to return it to circulation. Copper is often converted into sludge or stabilized waste and permanently removed from the materials economy. Once treated as waste, this copper rarely appears in recycling statistics or supply models.

As demand tightens, these uncounted losses become more consequential. Dissolved copper represents material that has already been mined, refined, transported, and paid for, yet is effectively removed from circulation long before end-of-life recovery is possible.

This gap exposes a limitation in how circularity is commonly defined. Recycling remains essential, but it largely addresses copper at the end of its life. It does not account for copper lost during use. In a constrained supply environment, circular strategies that overlook dissolved and dispersed copper leave a significant portion of material efficiency unrealized.

Understand why some copper never enters traditional recycling streams.

Related ElectraMet Resource

The Real Carbon Cost of Copper: Why Recovery Beats Recycling

Industry-Specific Implications

Copper’s changing role affects industries differently, but the underlying pressure is shared.

Defense Manufacturing

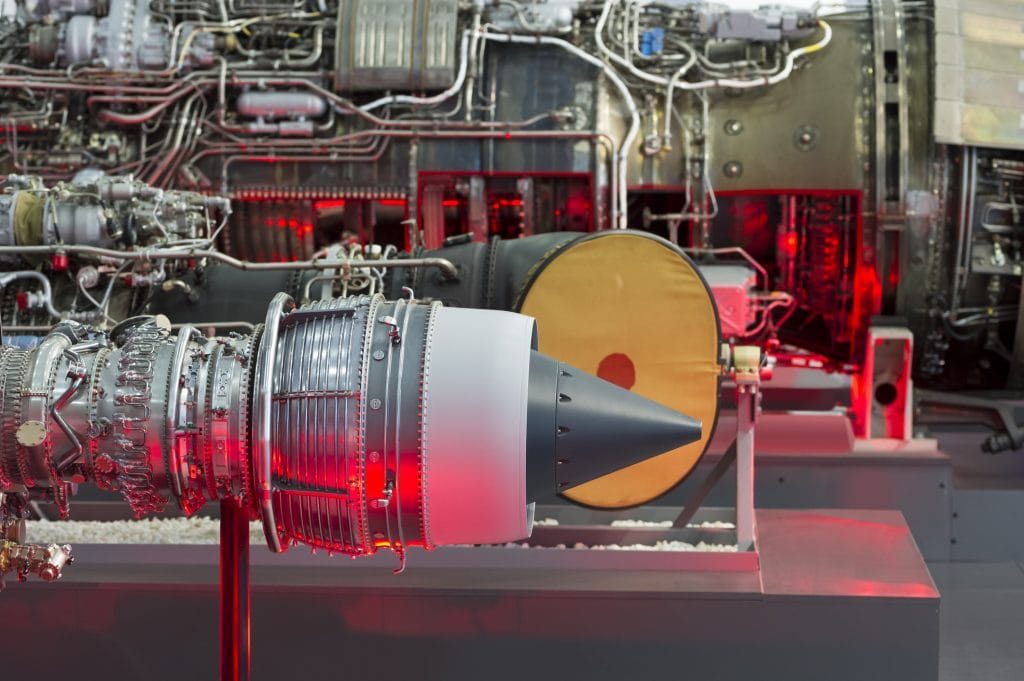

Defense systems are becoming more electrified, more networked, and more redundant. Platforms, facilities, and supply chains rely on copper-intensive electrical architectures to ensure reliability under extreme conditions.

At the same time, defense demand is rising alongside civilian electrification and AI infrastructure. These sectors compete for the same material base, increasing exposure to supply risk and volatility. For defense manufacturers, copper availability increasingly intersects with long-term planning, resilience, and security considerations.

Semiconductor Manufacturing

Semiconductor fabrication is among the most copper-intensive manufacturing environments in operation today. Copper supports interconnects, power delivery, process tools, and facility infrastructure.

Fabs also generate complex wastewater streams containing dissolved copper that must be carefully controlled to meet discharge limits. As semiconductor manufacturing scales to support AI and advanced packaging, copper demand increases both upstream and downstream.

Managing copper losses becomes not only a compliance requirement, but an operational efficiency and cost-control issue.

Copper Mining and Processing

For mining and processing operations, copper constraints appear earlier in the value chain. Declining ore grades increase throughput demands, while energy and water intensity rise per unit of copper produced.

Processing losses directly affect recovery economics. Copper that exits through tailings or water streams represents lost value as well as increased environmental and operational burden. Improving recovery efficiency and water management becomes a critical lever for maintaining performance under tightening supply conditions.

Explore how copper intensity, losses, and recovery challenges differ across defense, semiconductor manufacturing, and mining operations.

Related ElectraMet Resource

When Metals Are Too Valuable to Waste

The Overlooked Copper Stream: Industrial Wastewater

Across defense manufacturing, semiconductor fabrication, and mining operations, copper routinely exits industrial processes through wastewater. These losses occur upstream of traditional recycling pathways and are often treated solely as an environmental compliance issue rather than a supply consideration.

This copper is rarely accounted for in copper supply strategies, even though it has already passed through exploration, mining, refining, and manufacturing. Once dissolved into wastewater streams, copper is removed to meet discharge limits and typically discarded. At that point, it becomes both a regulatory obligation and a permanent material loss.

From a supply perspective, this distinction matters. Copper discharged through wastewater must be replaced from a supply chain that is increasingly constrained by long mine development timelines, declining ore grades, processing bottlenecks, and geopolitical risk. As demand tightens, these replacement requirements compound pressure on upstream supply.

Recovering copper from wastewater does not replace mining or traditional recycling. It addresses a different part of the copper lifecycle. By reducing avoidable losses within existing operations, recovery helps retain copper already in circulation and reduces dependence on new supply to offset inefficiencies.

This shift reframes wastewater treatment. Rather than functioning solely as a downstream compliance system, wastewater management becomes part of broader materials management. In a constrained supply environment, understanding where copper leaves industrial systems, and why, becomes as important as understanding where it is sourced.

Discover how dissolved copper quietly exits industrial operations.

Related ElectraMet Resource

Out of the Blue: Turning Copper Waste into Recovered Value

An Action Framework for Industrial Leaders

As copper shifts from a readily available input to a constrained industrial resource, managing it requires intent and visibility across operations. For industrial leaders, the goal is not to predict markets, but to reduce exposure by understanding and controlling how copper is used and lost.

A practical framework begins with a small number of focused questions:

-

Do we understand where copper enters our operations?

Do we understand where copper enters our operations?

This includes raw materials, utilities, infrastructure, and embedded systems, not just purchased copper inputs. -

Do we know where copper exits our systems?

Losses occur through products, scrap, emissions, and wastewater. Dissolved copper in wastewater is often the least visible and most persistent loss point. -

Have we quantified avoidable losses?

Copper removed solely for compliance represents material that must be replaced from a constrained supply chain. -

Are recovery options evaluated alongside compliance and operations?

Effective copper management considers recovery, discharge requirements, uptime, and system stability together rather than in isolation. -

Is copper treated as a planning variable?

Long-term facility design, infrastructure investment, and expansion plans increasingly depend on copper availability and cost stability.

Facilities that can answer these questions clearly are better positioned to manage cost volatility, supply risk, and regulatory pressure. In a constrained supply environment, disciplined copper management becomes a strategic capability rather than a reactive task.

Assess where copper enters, moves through, and exits your operations.

Sources & References

This page draws on analysis and reporting from S&P Global, the International Energy Agency, the International Copper Study Group, the U.S. Geological Survey, and other publicly available industry and policy sources addressing copper supply, demand, and infrastructure trends.