Introduction

For metal impurity removal from industrial wastewater, techniques like electrowinning have been used for decades. In today’s dynamic industrial landscape, there’s a growing need for more efficient, sustainable, and versatile solutions. We will explore the traditional process of electrowinning, its limitations, and why innovative and effective methods, such as ElectraMet’s have a place in EV battery recycling, semiconductor manufacturing, mining, and other industries.

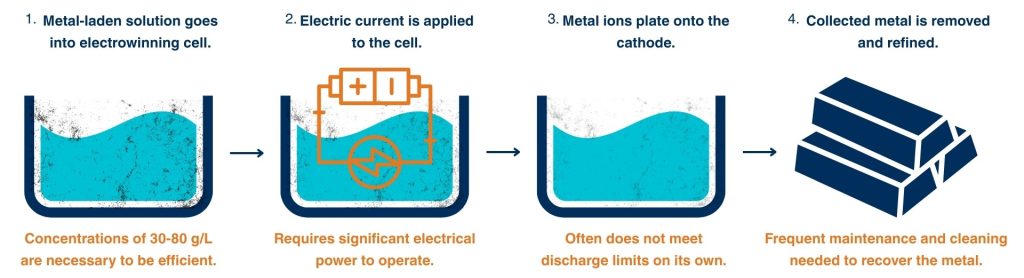

The Basics of Electrowinning

Electrowinning is the incumbent electrochemical process used to extract metal ions from aqueous solutions. The fundamental principle involves the use of electrical current to induce a reduction reaction at the cathode, resulting in the deposition of metal ions in a solid form. While electrowinning has been widely used, it comes with several limitations and environmental impacts that need to be addressed in today’s industrial context.

Limitations of Electrowinning

Energy-Intensive: Electrowinning is energy-intensive, requiring significant electricity consumption. The common answer to removing more dissolved metal is to increase amperage, overloading grids and introducing significant risk through excessive heating of equipment. A common pun is “if you haven’t seen smoke or fire, then you haven’t electrowinned.” This energy inefficiency not only adds to operational costs, but also has environmental and safety implications.

Removal Efficiency: While electrowinning can be effective for higher concentration applications, it does not achieve low levels of dissolved metal ions removal needed for asset recovery and environmental discharge compliance.

Maintenance and Downtime: Electrowinning systems can be complex and require frequent maintenance, leading to downtime and reduced overall efficiency. Removing stuck cathodes, cleaning and mining the baths, and lifting and hauling the recovered copper are all labor intensive and result in downtime.

Selectivity: Electrowinning is not capable of operating in diverse metal pools. The effectiveness of electrowinning varies for different metals and the lack of controls on amperage and voltage make it non-viable when dealing with a range of impurities in industrial wastewater.

The ElectraMet Difference

ElectraMet has revolutionized metal impurity removal with its innovative and sustainable technology. Here’s why it’s the superior choice:

Efficiency: ElectraMet’s process is highly efficient, achieving lower parts per billion (ppb) levels of metal impurity removal. It can effectively target both dissolved and particulate metal impurities.

Sustainability: Unlike electrowinning, ElectraMet’s technology eliminates ongoing waste generation, aligning with sustainability and environmental responsibility goals.

Cost-Effective: ElectraMet offers cost savings by reducing waste disposal costs, reducing labor, reducing complexity, optimizing process efficiency, and enhancing product quality.

Versatility: ElectraMet’s technology is adaptable and can target various metals, providing a versatile solution for different industrial processes. With finely tuned controls, ElectraMet can remove targeted metals while leaving others untouched, such as Cu2+ from Cobalt, Nickel, or Manganese streams.

Reduced Downtime: ElectraMet’s systems are robustly designed and automated maximizing planned uptime.

A Sustainable Future

As industries increasingly recognize the importance of sustainability, it’s essential to embrace innovative solutions that not only meet regulatory compliance but also contribute to environmental stewardship and operational efficiency. ElectraMet’s technology offers a pathway to a more sustainable future by addressing the limitations of traditional methods like electrowinning. Read our blog post on how you can achieve a circular economy.

Conclusion

Electrowinning is the leading commercial technology for metal impurity removal for product streams and compliance challenges with dissolved metals. ElectraMet’s advanced technology provides a more efficient, sustainable, and cost-effective solution for extracting dissolved metals from industrial processes where electrowinning has been applied . It’s time to transition to the future of metal recovery with ElectraMet and unlock the full potential of your industrial processes. Contact us today to learn more and schedule a demonstration of our groundbreaking technology.