Advanced Wastewater Treatment for Metal And Oxidant Removal

Upgrade your current Wastewater treatment processes:

Enable Chemistry and Metal Recovery to Reduce Total Costs

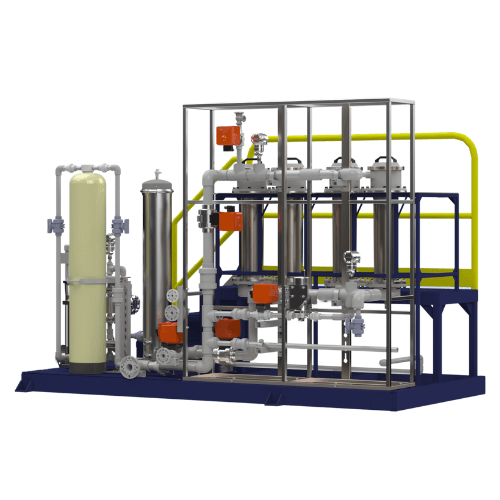

ElectraMet Wastewater Treatment Systems

Cutting-edge electrochemical systems, tailored for metal recovery, oxidant abatement, and acid reuse. Built for performance at any scale.

α – Discharge Compliance

Dive deeper into how Alpha can fortify your compliance strategy and enable absolute ownership over metals removal at your site.

φ – Product Purification

Phi optimizes your purification processes, achieving exceptional product quality and efficient metals recovery across your facility.

δ – Bridge Efficiency Gaps

Delta enhances metal removal technology, reducing energy use and improving treatment effectiveness for mid-range concentrations.

γ – Oxidant Decomposition

Protect your assets and the environment with the Gamma system, engineered for safe abatement of oxidants to enhance water reuse.

ω – Bulk Removal

Omega’s bulk recovery technology optimizes sustainability and metal recovery across mining and microelectronics applications.

ι – Onsite Evaluation

The Iota is a 1:20 scale system for metals and peroxide removal across various industrial and laboratory applications.

Industries we Serve

How to Get Started

Feasibility Testing

Before full-scale implementation, ElectraMet analyzes your stream to evaluate removal efficiency and recovery feasibility. You send us a water sample and ElectraMet performs comprehensive testing and reporting to capture the impact of your operation.

Pilot Installation

ElectraMet executes onsite pilot studies to gauge process stream variations that impact commercial design. The pilot provides extensive data to design the best solution for your site while also familiarizing your staff with ElectraMet systems.

Implementation

The commercial system is designed to address operations and sustainability goals. ElectraMet systems integrate seamlessly into site building management or SCADA systems to deliver on contracted specifications.

How Can ElectraMet's Wastewater Technology Help You?

Discharge Compliance

Real-time monitoring and analysis reacts to process changes and assures specification.

Impurity Removal

Target and remove Cu & Mn impurities from metals leachate while optimizing yield.

Eliminate Waste

Eliminate hauling, resin change-outs, and offsite regeneration to reduce Scope 3 emissions.

Selective Metal Recovery

ElectraMet technology allows you to select the targeted metal for removal and recovery.

Oxidant Abatement

Destroy hydrogen peroxide and enable acid reuse. Reduce oxidant load in industrial wastewater.

Asset Protection

ElectraLink collects data and communicates insights to notify your team of process upsets.