Industrial wastewater treatment has been a critical process for many years, as companies look to reduce their environmental impact and comply with increasing regulations. Over time, several common industrial wastewater treatment solutions have emerged, each with its advantages and limitations. In this blog post, we’ll explore the most common industrial wastewater solutions and introduce ElectraMet’s solution that is changing the game in wastewater treatment.

The History of Industrial Wastewater Treatment

The history of industrial wastewater treatment dates back to the early 1900s when simple physical treatments such as sedimentation, screening, and flotation were introduced. Over the years, several new treatment solutions have emerged, including chemical coagulation, filtration, and ion exchange. While these solutions have been effective in treating wastewater, they have several limitations, including high costs, the production of sizable waste streams, and the need for frequent maintenance and monitoring.

Common Industrial Wastewater Solutions

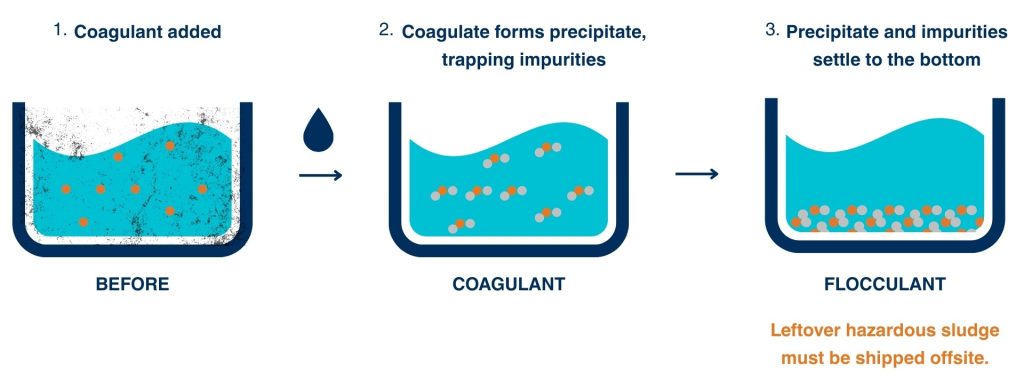

Chemical Coagulation

Chemical coagulation is one of the most commonly used wastewater treatment solutions for the industrial sector, involving the addition of a coagulant to wastewater to create larger particles that can be removed more easily through settling and/or filtration. While chemical coagulation can be effective in removing contaminants, it can be costly and produces a waste stream that requires disposal offsite.

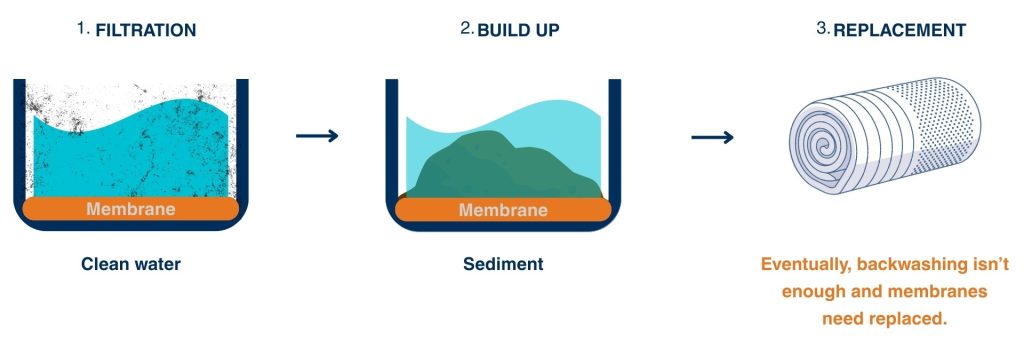

Filtration

Filtration involves passing wastewater through a filter to remove suspended particles. Filtration can be effective, but it requires frequent maintenance and replacement of the filtration media.

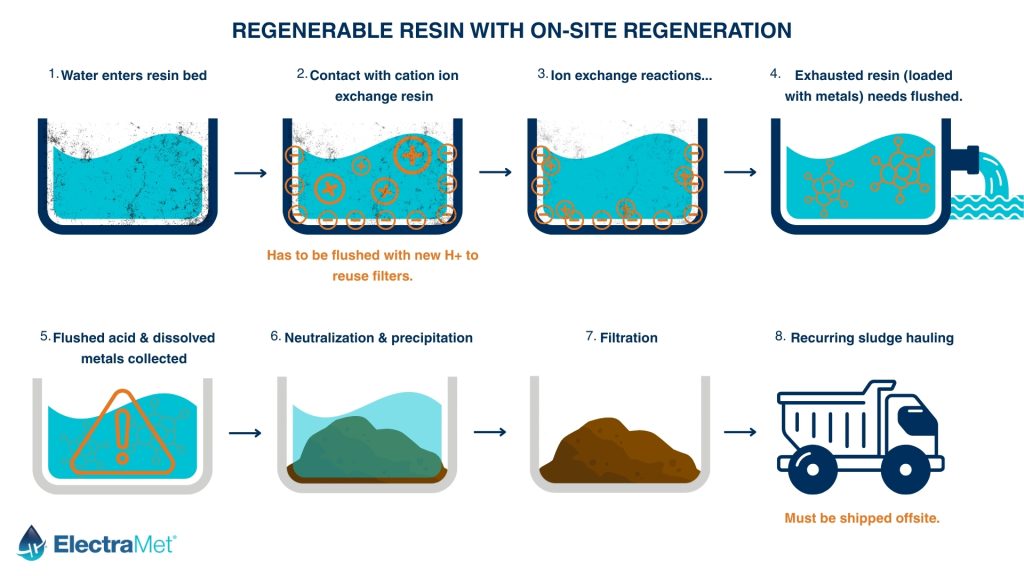

Ion Exchange

Ion exchange involves passing wastewater through a resin bed, which selectively removes dissolved contaminants by exchanging ions with the resin. While ion exchange can be effective, it often requires the disposal of a waste stream and can be costly to operate. In addition, the resins can be adversely affected by other compounds in the wastewater such as hydrogen peroxide and organics, among others.

ElectraMet: A New, Futuristic Wastewater Treatment Solution

At ElectraMet, we offer a next-gen wastewater treatment solution that is revolutionizing the industry. Our solution is chemical-free and uses low amounts of power, taking up a small footprint in an industrial complex. ElectraMet’s system doesn’t require settling tanks, coagulation, or filter presses, and it produces no waste stream. Unlike other wastewater treatment solutions, ElectraMet can return the metal as a pure sheet or an oxide to the customer, eliminating the need for costly waste disposal and producing a higher quality product that is more desirable for industrial applications.

Final Thoughts

Industrial wastewater treatment has been a critical process for many years, with several wastewater treatment solutions emerging over time. While these solutions have been effective, they have several limitations, including high costs, waste stream production, and frequent maintenance requirements. At ElectraMet, we offer a new solution that is revolutionizing the industry by eliminating these limitations and producing a more efficient and cost-effective solution for industrial wastewater treatment. With ElectraMet’s system, companies can enjoy higher quality products and lower costs, making it a smarter choice for the future. If you are interested in learning more, feel free to listen to our discussion and our approach for reclaiming heavy metals from wastewater streams, and the future of the industry.