In the realm of microelectronics manufacturing and various industrial processes, copper is a common impurity in process water and wastewater streams. While it plays a crucial role in many applications, excessive copper can pose significant environmental and health risks. Therefore, industries must take steps to effectively remove copper from their wastewater before discharging it into the environment. Here are 5 tips to meet discharge compliance.

This comprehensive guide aims to shed light on the challenges posed by copper contamination in industrial process water and wastewater. It explores various copper removal methods, such as ion exchange and chemical coagulation, delving into their limitations and drawbacks. Furthermore, we introduce ElectraMet’s revolutionary solution, which offers a sustainable and innovative approach to copper removal.

Understanding the Copper Challenge

Copper is often recognized as a critical mineral. This has created a copper supply gap as copper is essential in various industries due to its exceptional conductivity and versatility. However, its criticality extends beyond its utility. Copper has been designated as critical because of its vital role in technology, industry, and renewable energy applications. Read more about how much copper is in lithium-ion batteries.

Definition of Critical Minerals:

Critical minerals are natural resources essential to the economic and security interests of a nation, yet vulnerable to supply chain disruptions. These minerals underpin the functioning of key sectors such as defense, clean energy, electronics (printed circuit board), and semiconductor manufacturing.

Why is this significant? In the current global context, sustainability is a paramount concern. It entails a commitment to utilizing resources efficiently and eliminating waste. Copper plays a vital role in various industrial processes, contributing significantly to the functioning of our society. However, it is equally crucial to strike a balance between its essential applications and the environmental consequences of excessive mining. The solution to this problem is achieving a circular economy within your own operation.

Traditional copper removal methods have been employed for decades to address the challenge of copper contamination in industrial process water and wastewater. In this section, we explore these conventional approaches and delve into their mechanisms and applications.

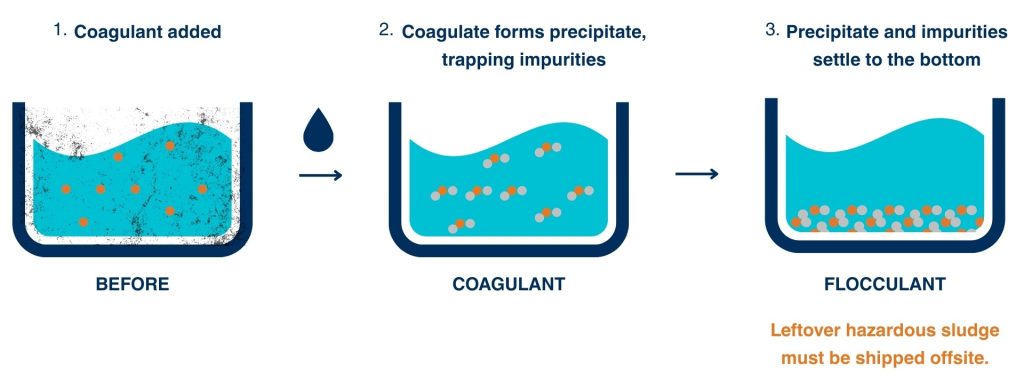

Chemical Precipitation (Coagulation)

Chemical precipitation, often referred to as coagulation, involves adding specific chemicals to water containing dissolved copper. These chemicals, which may include lime, sodium hydroxide, or ferrous sulfate, induce a chemical reaction that causes copper to form solid particles. These particles can then be removed from the water through settling or filtration.

Pros:

- Effective in removing copper.

- Relatively simple to implement.

Cons:

- Requires a significant amount of chemicals.

- Produces a substantial amount of sludge.

- Often necessitates additional treatment steps to ensure the water is safe for discharge.

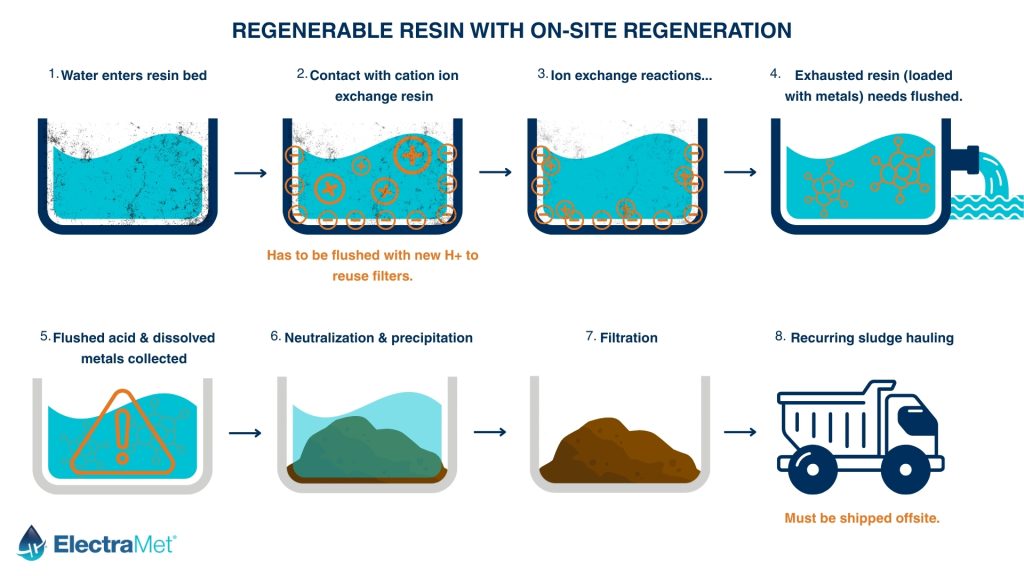

Ion Exchange

Ion exchange is a process that focuses on removing copper ions from water by exchanging them with other ions present in a resin bed. As water passes through this resin bed, the charged particles within it attract and retain copper ions.

Pros:

- Effective at copper ion removal.

Cons:

- Generates a significant amount of wastewater.

- May require additional treatment steps to ensure water quality for discharge.

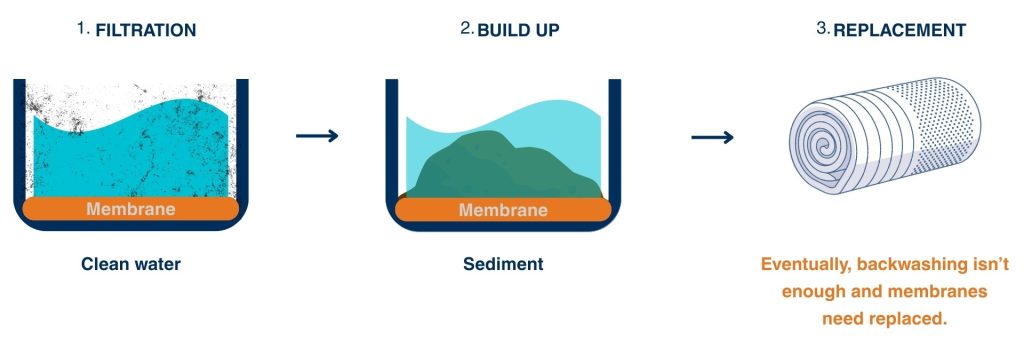

Membrane Filtration

Membrane filtration is a physical separation process that employs a semi-permeable membrane to remove copper and other contaminants from water. Most of the water flows through the membrane, creating a permeate stream that leaves contaminants behind in a concentrated stream. While this method can be effective, it tends to be expensive, and the membrane may require frequent replacement.

Pros:

- Effective in removing copper and contaminants.

Cons:

- Can be costly, particularly in terms of membrane replacement.

- May require maintenance and monitoring.

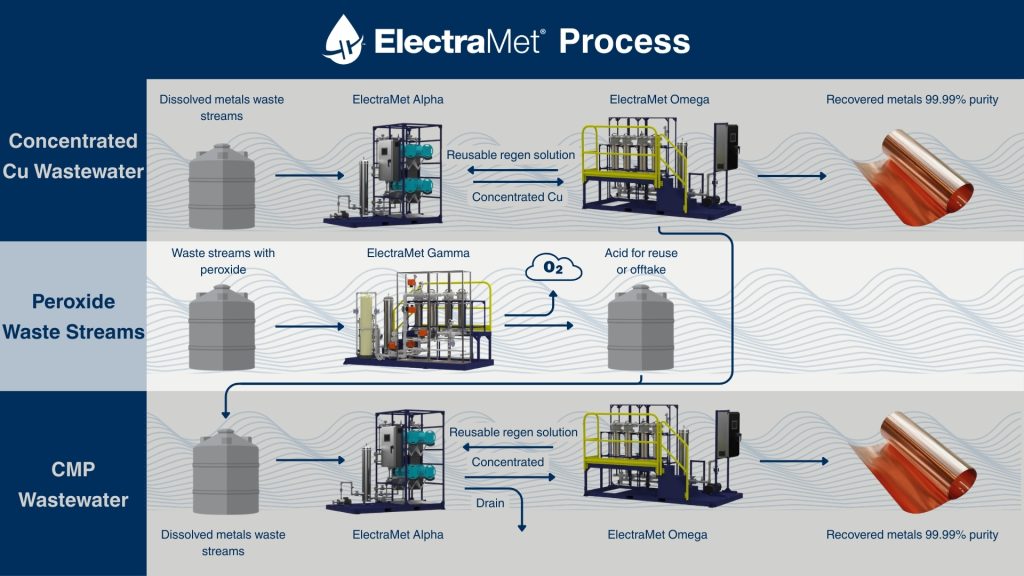

ElectraMet’s Revolutionary Copper Removal Solution

Now, here’s the groundbreaking aspect – ElectraMet’s innovative solution. We approach things uniquely.

ElectraMet’s Approach:

We’re experts in capturing and selectively recovering metals from wastewater. What makes us unique? Our fully automated process doesn’t just remove impurities like copper; it captures and returns it in its purest form, ready to be used again. No need for lots of chemicals, and we’re eco-friendly.

A Sustainable Future:

Remember, copper is a critical mineral. As the world moves towards sustainability, using copper efficiently is key. ElectraMet helps by reducing the need for more mining and eliminating the waste associated with it.

Unmatched Advantages:

Here are the benefits you receive with ElectraMet:

Cost-Effective: Say goodbye to high chemical costs and waste disposal fees.

Guaranteed Compliance: Automated system keeps you within discharge limits.

Environmentally Friendly: Use very little electricity and produce no waste.

Increased Revenue: Reuse the pure copper sheets we recover, turning waste into profit.

Meeting Compliance Goals

In today’s environmentally conscious world, industries are increasingly held accountable for their impact on the environment. Regulatory agencies have established strict guidelines governing what can be discharged into natural ecosystems, including water bodies. Here are the Effluent Guidelines from the EPA. This is where the importance of effective copper removal comes into play.

Environmental Regulations and Standards

Various environmental regulations and standards have been put in place to safeguard the delicate balance of ecosystems and to protect human health. These regulations specify acceptable limits for various contaminants, including copper, in wastewater and industrial discharges. Industries are legally obligated to adhere to these limits and ensure that their operations do not harm the environment or public health.

Maintaining Ecological Balance

Copper, while essential in small quantities, can be detrimental in excess. When released into water bodies, it can disrupt aquatic ecosystems by poisoning aquatic life, such as fish and other aquatic organisms. This not only harms the biodiversity of these ecosystems but also affects the delicate balance of food chains, ultimately impacting the overall health of aquatic environments.

Ensuring Public Health and Safety

Excessive copper in drinking water or recreational water bodies poses serious health risks to humans, including gastrointestinal problems, liver damage, and neurological disorders. Effective copper removal is essential for safeguarding public health and preventing these risks. Failing to do so not only results in non-compliance but also endangers the well-being of communities and ecosystems

Environmental Consequences

Improper copper removal can result in the release of excessive copper into the environment. This can lead to the contamination of natural water bodies, disrupting ecosystems and harming aquatic life. Over time, the cumulative effects of copper pollution can lead to long-lasting damage to the environment that may be permanent.

Human Health Impacts

Copper contamination in drinking water can have severe health consequences for humans. Prolonged exposure to elevated copper levels can lead to gastrointestinal problems, liver damage, and neurological issues. This poses a direct threat to public health and can result in increased healthcare costs and a diminished quality of life for affected individuals.

Regulatory Consequences

Failing to meet copper discharge limits and environmental regulations can result in legal repercussions and fines for industries. Regulatory bodies take violations seriously, and the financial penalties can be substantial. Additionally, ongoing non-compliance can damage a company’s reputation and credibility within its industry.

Economic Considerations

Inefficient copper removal methods can be costly in terms of chemical usage, disposal of sludge, and potential fines for non-compliance. Industries that do not invest in effective copper removal may find themselves facing higher operational costs and financial losses in the long run.

In summary, effective copper removal is not merely a matter of regulatory compliance; it’s a critical component of responsible environmental stewardship and a safeguard against the potential risks to both ecosystems and human health. Industries that prioritize proper copper removal contribute to a cleaner environment, healthier communities, and long-term economic sustainability.

Industries We Serve

ElectraMet’s versatile technology finds applications across various industries. Our solution addresses the unique metal removal needs of each sector, from semiconductor manufacturing to EV battery recycling, ensuring compliance and sustainability.

Conclusion

Removing copper from industrial process water and wastewater is essential for compliance and environmental responsibility. ElectraMet’s innovative solution offers a sustainable and groundbreaking approach, reducing waste, conserving resources, and enabling industries to meet their goals while contributing to a more sustainable future.

Ready to level up your copper removal process and ensure compliance? Contact ElectraMet today to discuss our sustainable solutions and take the first step toward a cleaner, more responsible industrial operation.