Background

A semiconductor manufacturing technology foundry uses a technique known as chemical-mechanical polishing/planarization (CMP) to planarize it’s semiconductors during the standard production process. The industrial wastewater produced as a byproduct (~3500 gal/week) requires treatment and frequently contains copper concentrations that are above the permitted discharge limit (>2.07 ppm), as well as other chemicals like silica and hydrogen peroxide that can complicate treatment options.

Challenges

Treating copper– and peroxide-bearing CMP wastewater often requires shipment to a 3rd-party treatment facility, which can be expensive. Other on-site options require large amounts of chemicals and are labor-intensive, making off-site treatment the preferred choice.

ElectraMet Copper Removal Process

By electrochemically removing and recovering dissolved copper, ElectraMet has proven to be a simple and efficient on-site solution for CMP wastewater treatment, even in the presence of other contaminants. ElectraMet uses an automated process to treat CMP wastewater directly at the customer site for a fraction of the cost of off-site treatment and with minimal operator interaction.

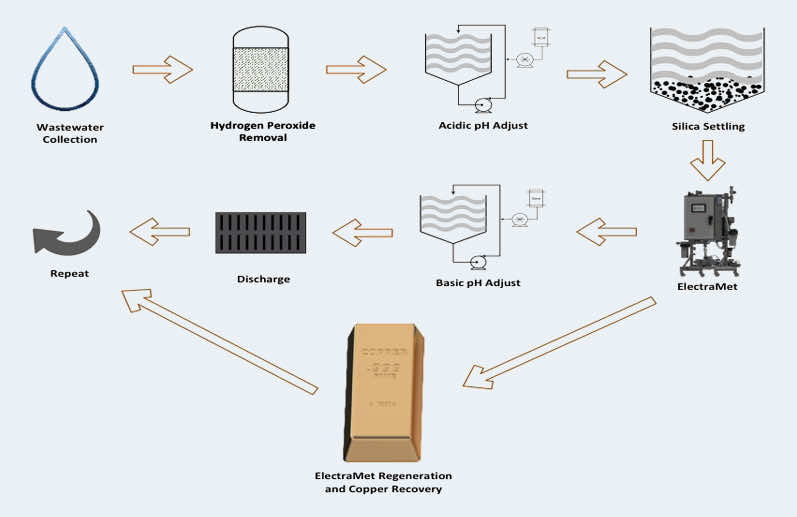

First, the produced wastewater (containing copper, peroxide, and silica) is transferred from the collection tank to the process tank through a packed bed to remove hydrogen peroxide. Then a pH recirculation loop is activated to drop the pH of the wastewater from near neutral to acidic, which causes the dissolved silica to crash out of solution and improves the removal performance of ElectraMet. Once the pH is within range, the silica is allowed to settle to the bottom of the conical process tank for a sufficient time to ensure that the tank outlet to ElectraMet is above the settled silica line.

Next, the ElectraMet unit is activated and begins to remove copper from the wastewater for a specified amount of time. Once the ElectraMet treatment has completed, the ElectraMet cartridges will begin a regeneration step, during which the removed copper is flushed out of the cartridges into a separate acidic solution which will eventually build up in copper concentration. At the same time, the treated water begins a final pH adjustment to increase the pH for discharge compliance. Once the pH is within an acceptable range, the process tank is discharged and the system resets.

The full cycle of the ElectraMet process allows for copper to be removed from wastewater, regenerated into a concentrated stream, and eventually recovered in solid form by plating. The automated system allows for more consistent and efficient operation and negates the need for operator interaction (aside from regular maintenance), which is an added benefit when scaling up. Because ElectraMet does not rely on chemicals for its treatment (other than acid and base adjustments), the overall operation is simpler, and the footprint is much smaller, than other on-site options.

Results

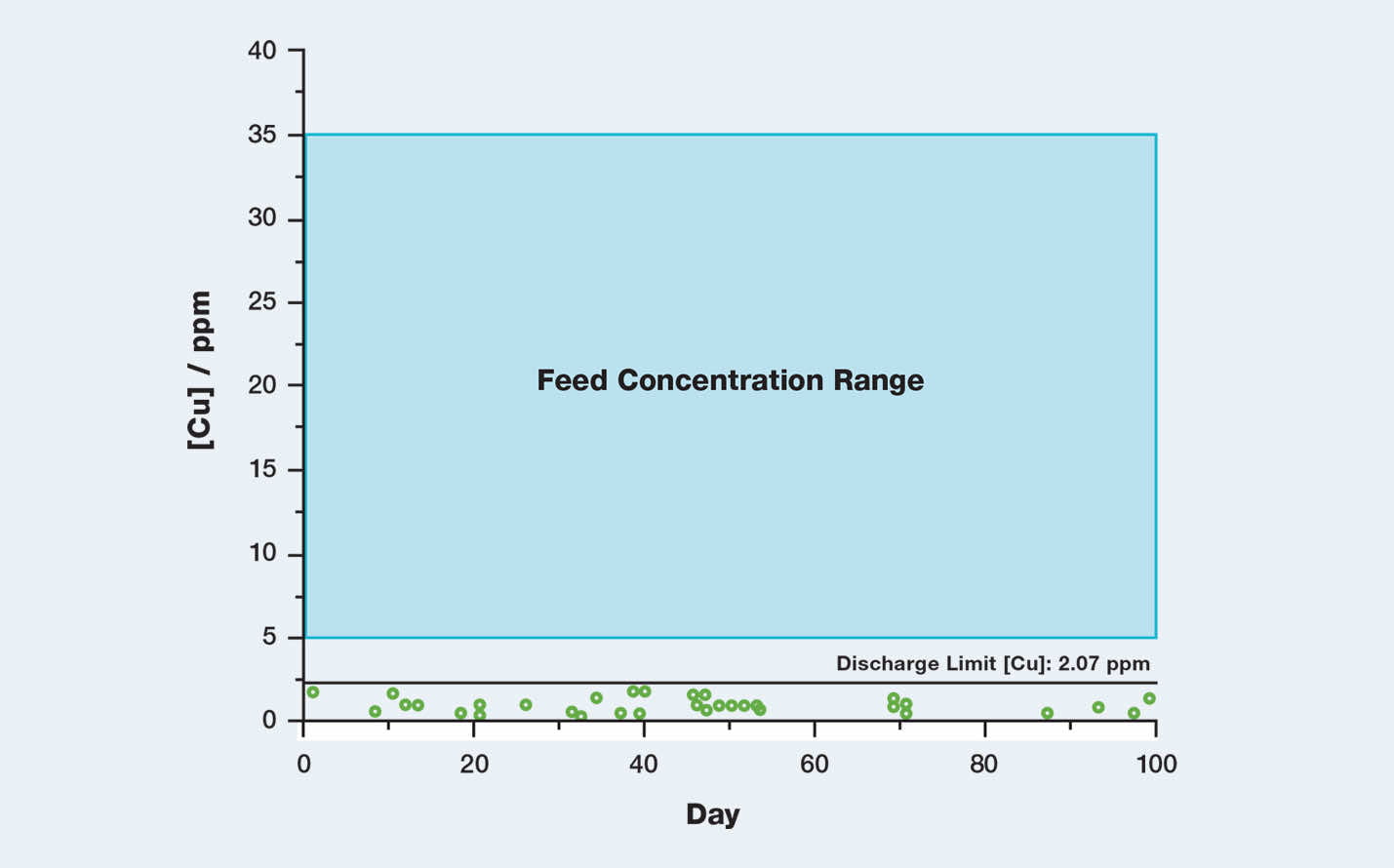

Initial copper concentrations for this specific wastewater ranged from 5–35 ppm and initial hydrogen peroxide concentrations ranged from 500–1500 ppm. Hydrogen peroxide removal is verified using peroxide test strips. Copper concentrations are obtained by the customer using a Hach DR900 colorimeter, with plans to incorporate an in-line copper analyzer at this facility.