ElectraMet specializes in transforming industrial wastewater streams into valuable resources through innovative metal recovery solutions. Our cutting-edge systems are designed to selectively remove and recover a wide range of metals, ensuring compliance with environmental regulations, enhancing operational efficiency, and contributing to sustainability initiatives. Whether you are dealing with copper, silver, zinc, or other metal impurities, our tailored solutions deliver unparalleled performance, reducing waste and generating revenue from recovered materials.

Explore our expertise and discover how ElectraMet can help you optimize your processes and achieve your sustainability goals.

Challenges:

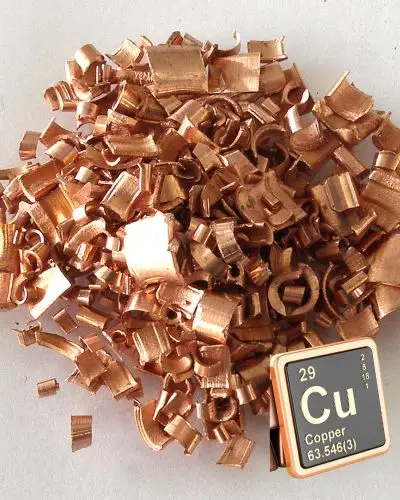

Copper is a critical component in many manufacturing processes for electronics due to high electrical conductivity, resistance to corrosion, malleability, thermal conductivity, and longevity. Due to several of these factors, it also presents waste treatment challenges for several markets.

Common sources of copper in wastewater include manufacturing processes, polishing processes, and acidic or etching rinses. Copper tends to form stable complexes in wastewater, making traditional recovery methods inefficient and costly.

Solution:

ElectraMet’s advanced electrochemical systems ensure efficient and cost-effective copper removal and recovery from complex waste streams, achieving compliance and enabling the reuse or sale of high-purity copper. Systems are scalable to address production needs as the plant grows and changes over time.

Benefits:

Challenges:

Manganese is commonly found in industrial wastewater from battery production, electronics, mining, and other manufacturing processes. Its removal is critical due to its toxicity at high concentrations, contamination issues with mid-stage and finished products, and impact to water reuse membranes.

Solution:

ElectraMet’s advanced electrochemical systems target and remove manganese ions from wastewater, ensuring compliance and improving water quality. In some applications, manganese is trimmed to attain a desired ratio, such as lithium ion battery ratios. Systems are scalable to address production needs as the plant grows and changes over time.

Benefits:

Challenges:

Silver is used extensively in electronics, medical devices, and various industrial applications. Wastewater from these processes often contains silver, which must be removed to prevent environmental contamination and recover valuable resources. Silver plating, extraction, and rinse processes typically involve expensive additive chemistry that is typically discarded, adding additional cost and environmental challenges for silver processes.

Solution:

ElectraMet’s advanced electrochemical systems recover silver from process and wastewater, turning waste into a valuable resource while ensuring compliance with environmental standards. Targeted removal enables chemistry reuse to extend process solution lifespan, further optimizing production costs and eliminating downtime for changeouts. Systems are scalable to address production needs as the plant grows and changes over time.

Benefits:

All Rights Reserved.

All material appearing on the ElectraMet® website (“content”) is protected by copyright under U.S. Copyright laws and is the property of ElectraMet®. Copying, reproducing, distributing, publishing, displaying, performing, modifying, re-broadcasting, creating derivative works, transmitting, exploiting any such content, distributing any part of this content over any network, including a local area network, selling or offering it for sale, and using such content to construct any kind of database, website, or other work is expressly prohibited. Altering or removing copyright or other notice from copies of the content on ElectraMet®’s website is expressly prohibited.