Revolutionary Treatment for Strong Peroxide Mixtures and Oxidants

Ammonium hydroxide (NH₄OH) is typically combined with hydrogen peroxide (H₂O₂) in a 3:1 mixture to create a base piranha solution. While 3:1 is typical, base piranha can be created with alternate ratios. Base piranha removes organic residues from substrates and is a strong oxidizing agent that hydroxylates surfaces, making them more compatible with water.

Base piranha is a popular choice for cleaning photoresist and organic resides from semiconductors. While catalase has shown some success with removing hydrogen peroxide oxidants from base piranha, reaction kinetics are poor at higher concentrations. It also presents high potential for organic fouling in downstream membranes or media. Activated carbon is not viable for base piranha due to limited effectiveness >500 mg/L [H₂O₂]. Innovation is needed to provide better options for modern manufacturers. ElectraMet specifically developed the Gamma System to fill this innovation gap for peroxide oxidant abatement in base piranha solutions.

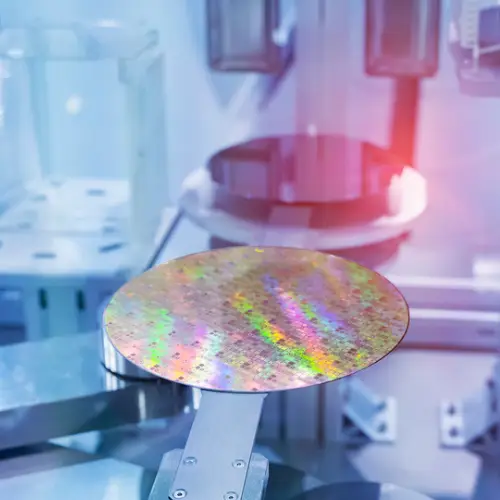

Sulfuric acid (H₂SO₄) or hydrochloric acid (HCl) are typically combined with hydrogen peroxide (H₂O₂) in a mixture to create piranha acid, a highly reactive solution used to remove photoresist and organics from silicon wafers. It is also used in the wet etching process within the fab.

Catalase and activated carbon are impractical due to excessive cost, poor reaction kinetics, component degradation, and production of organic foulants. Use of piranha acid with limited abatement solutions has led to significant risks for regulatory compliance and downstream assets. As a result, innovation is needed to abate the H₂O₂ while eliminating unexpected operating expenses for hauling, treatment, repairs, and other unplanned expenditures. ElectraMet specifically developed the Gamma System for peroxide abatement in piranha acid solutions.

ElectraMet’s innovation engine has produced the Gamma System for piranha solution abatement. System components are specifically designed for aggressive chemistries while the Gamma’s catalytic media achieves unrivaled reaction kinetics without producing unplanned byproducts.

Achievement of zero-liquid discharge (ZLD) and zero-waste (ZW) initiatives are now within your reach. The Gamma System, a revolutionary abatement solution for aggressive oxidants, effectively treats piranha acid (HCl & H₂SO₄) and base piranha (NH₃) streams at elevated concentrations across the widest pH range without volume limitations (1 liter/min to >1000 liters/min).

Advanced analytics and automation are standard for all ElectraMet systems, allowing manufacturers to focus on their core competencies.

The Gamma System utilizes advanced process controls and catalytic media to convert hydrogen peroxide (H₂O₂) to water (H₂O) and oxygen (O₂)

All Rights Reserved.

All material appearing on the ElectraMet® website (“content”) is protected by copyright under U.S. Copyright laws and is the property of ElectraMet®. Copying, reproducing, distributing, publishing, displaying, performing, modifying, re-broadcasting, creating derivative works, transmitting, exploiting any such content, distributing any part of this content over any network, including a local area network, selling or offering it for sale, and using such content to construct any kind of database, website, or other work is expressly prohibited. Altering or removing copyright or other notice from copies of the content on ElectraMet®’s website is expressly prohibited.