Industry: Microelectronics

Process: Silver Recovery

Benefits:

- Higher value from recovered pure silver

- Removal and compliance assurance

- Eliminate sludge processes and ion-exchange

- Reduced labor hours through integrated automated process

Background

Microelectronics manufacturing uses diverse raw materials, chemicals, and processes. As part of the production finishing process, chemistries diluted with deionized water (DI) are used to remove particles, residues, metallic impurities, and organic contamination from the sensitive components in rinsing baths. While assuring quality and longevity for the manufactured components, this rinse requires wastewater treatment to address the dissolved metals removal for asset recovery and discharge compliance regulations placed on the facility. Silver metal found in the rinse water was targeted for treatment and disposal according to EPA and local regulatory guidelines. Recovery of the silver is highly desirable due to its value. Ion-exchange (IX) was the traditional treatment method, which required heavy amounts of processing and media/vessel changeouts to capture the silver asset.

Challenges

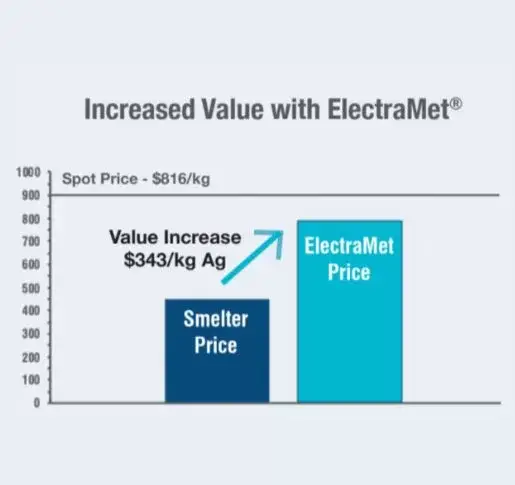

A large printed circuit board (PCB) manufacturer produces silver-laden wastewater from rinse baths, also called drag-out baths. The site was using ion-exchange to remove the silver to meet NPDES permit limits and selling the saturated resins to a smelter to reclaim only 55% of the silver value, or $449/kg. Production for the plant was forecasted to increase, which translated to an increase in resin change out frequency and associated costs.

Challenge

Low asset recovery revenue from silver

Increased footprint, costs, & bed changeouts due to production increase

No verification for removal or compliance

Solution

Targeted silver (Ag) recovery as >99.9% silver powder

Automation with small footprint automatically responds to production changes

Integrated treatment with sensors delivers process transparency & optimization

Impact

Increased silver revenue by $1.7 MM (97% v. 55% spot price)

Reduced dedicated labor by 50% (1/2 FTE); eliminated > 20,000 lbs. of consumed IX resin

Zero breakthroughs have occurred with 100% equipment uptime

Proven Results | Case Study

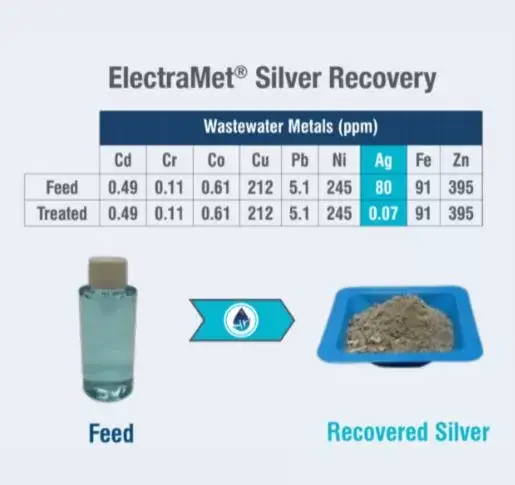

The manufacturing process of a microelectronics manufacturer produced waste byproducts containing elevated levels of silver of 40 ppm – 80 ppm and varying amounts of organic compounds. The site permit allowed for 0.1 ppm in the effluent discharge. Site expectations are to recover the silver for recycling while meeting discharge compliance. ElectraMet’s automated process was implemented in phases to control the changeover from ion-exchange, resulting in an 8-week implementation and approval process.

Over an 8-week period, the site was able to:

- Increase vale of recycled silver by $343/kg

- Eliminate ion-exchange (IX) resin replacement and chemistry

- Reallocate 1/2 FTE to production site

Additional observed benefits include:

- eliminated > 20,000 pounds of annual IX consumption,

- reduced operator hours due to automation and analytics which informed adjustments,

- analytics-informed upstream process troubleshooting maximized uptime and production quality, and

- increased personnel time spent on preventative maintenance for other systems.